Updated: 7 November 2004

An adjustable, DC, current-limited, breakdown

voltage tester [BVT] -- also known as a high-potential

tester, or "hi-pot" -- can be used for non-3destructively measuring

the voltage withstanding ability of relays, capacitors, transistors

and silicon rectifiers. A BVT can be used to test amplifier-tubes for

the presence of gas, and oxide-cathode type [8877, et cetera]

amplifier-tubes for the presence of sputtered gold. A BVT can help

you identify a tube that could seriously damage your amplifier if you

inadvertently plugged it in.

For most amateur radio applications, a maximum voltage capability of

15kV is adequate. For testing commercial components, 40kV or more is

usually needed.

Troubleshooting an RF power amplifier without a BVT is difficult and

problematic. Building an RF power amplifier without a BVT is

risky.

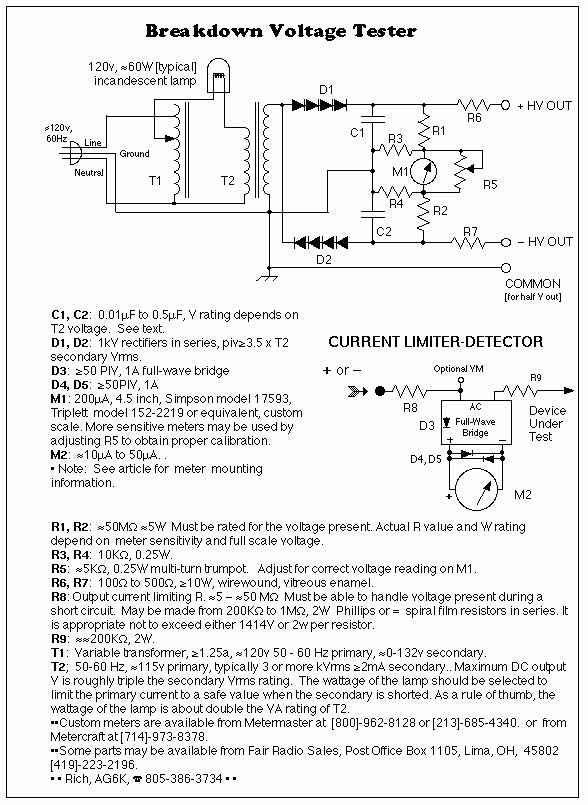

An adjustable transformer, T1, delivers

approximately 0-132vac to the primary of the HV transformer, T2. A

120v, incandescent lamp is used to limit the primary current in T2. A

full-wave voltage-doubler rectifier with capacitor filters is used to

produce the DC. R8 protects the device under test [DUT] from

excessive current during testing. The typical current during a test

is 2 to 100 uA.

- A voltage-quadrupler could be used instead of the voltage-doubler.

Quadruplers have one advantage and two trade-offs: Only half as much

secondary voltage is needed from T2. And four filter capacitors are

required instead of two. If a voltage-quadrupler is shorted, two of

the four filter capacitors discharge through two of the rectifiers

and the transformer secondary winding. This can damage rectifiers

and/or the transformer. - If a quadrupler is used, it is appropriate

to use long leakage path current limiting resistors in series with

all of the capacitors and a robust MOV across the transformer

primary.

Sources of T2 : A 50 - 60 Hz HV transformer from a: junked

copy-machine, a neon sign, or an old oscilloscope should work

acceptably.

Construction Notes - Due to the high

voltage levels, the ideal material for constructing a BVT is not

metal. Polyurethane varnished plywood, Lexan®

[polycarbonate], acrylic, or fiberglass are satisfactory

choices. A metal cabinet with a non-conductive front-panel and

chassis can also be used.

It is not good engineering practice to pack the components in a BVT

too tightly. In dry air, at sea-level, 1kV will jump about 1mm. In

moist air and at elevations greater than sea level, less voltage is

needed to jump the same distance.

To minimize corona current-leakage into the air, solder connections

that are at high-potential should be rounded "blobs." Avoid using

sharp points on conductors. Corona-effect is easy to check for: In a

darkened room, turn the voltage up to maximum and watch for blue

lights accompanied by a hissing sound and the odor of ozone.

[O3]. If needed, apply more solder and/or smooth trouble

spots with a file. Mounting components too close together can also

cause corona problems.

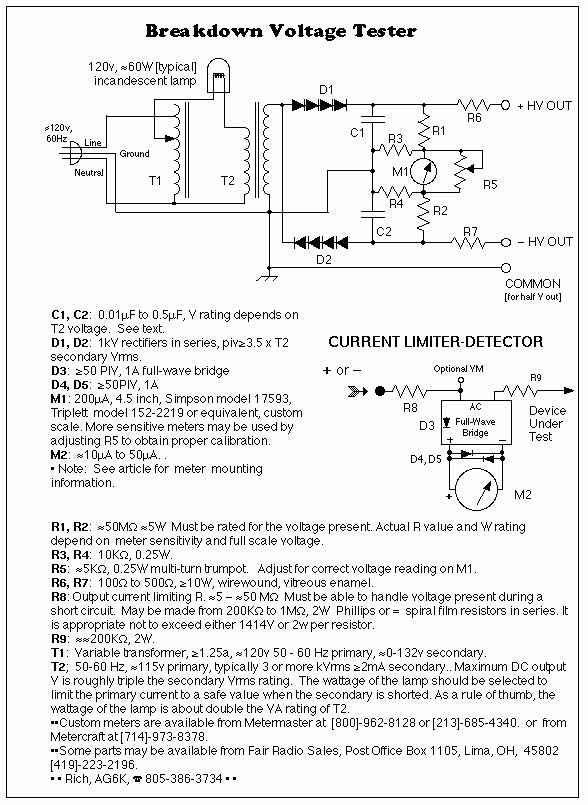

Current Limiter/Detector--R8/M2 is at high potential--so these

components should not be placed close to M1, which is at

ground/common potential. M2 and R8 should be mounted on an insulated

panel with no low potential conductors nearby. The current

limiter/detector is wired to banana-jacks so that it can be connected

to the positive or to the negative output terminal as needed.

D1 and D2 can be made from a series of individual 1kV diodes or a

series of multi-diode HV low-current rectifier units [a.k.a.

focus rectifiers]. So-called "equalizing-resistors" and

"equalizing-capacitors" should NOT be connected across modern

rectifier diodes. Use diodes with similar ratings and they will

equalize themselves.

The basic technique behind non-destructive voltage

testing is: slowly increase the applied voltage across the DUT until

a small current flows through the device. Record the V and stop the

test. If the voltage were allowed to increase beyond this critical

point, the component could be damaged. The applied voltage usually

does not need to remain on the DUT for any longer than it takes to

read the voltmeter, M1, and the current-meter, M2. For testing

devices with lower breakdown voltages, only half of the doubler

should be used. One end of the DUT is connected to Common instead of

to one of the HV OUT terminals. Thus, the voltage readings on M2 must

be divided in half. If the breakdown voltage of the DUT is expected

to be less than 1000v, you may want to connect a DMM from the output

side of R8 to Common so that the voltage can be read more accurately.

Be careful. Most DMMs can not safely tolerate more than 1000v without

using a voltage multiplier probe.

Vacuum-capacitors and vacuum-relays should be tested for gas before

installation. I have seen new, unused vacuum-devices that were

defective due to very slow air leaks. Such leaks typically show up

several years after manufacture. In use, a gassy glass-envelope

vacuum-relay can often be identified because the ionized air inside

emits a blue light around the open contacts. However, the ionization

in a defective glass-envelope vacuum-capacitor is usually deep inside

the concentric meshed plates and can not be seen. Variable

vacuum-capacitors should be tested with the plates fully meshed. When

a vacuum-capacitor goes bad in an amplifier, reduced PEP in one

result. However, other things can cause the same problem. When

troubleshooting an amplifier, it is a good idea to routinely test all

of the vacuum capacitors and vacuum relays with a BVT.

Vacuum-capacitors that have been in storage for a long time may

develop "whiskers"--microscopic filaments of copper. Sure, it sounds

weird. This anomaly causes the breakdown-voltage to initially be

lower than normal. It is possible to burn-off these whiskers. During

the process, the capacitor may self discharge--as indicated by a

"tink" sound. Repeatedly forcing the capacitor to self discharge will

result in a decrease in breakdown voltage. Five tinks is usually a

good point to stop.

Semiconductor testing is important when building HV power supplies

that contain groups of series-connected rectifier diodes. If one or

more of the rectifiers fails during use, it could start a

"domino-effect" and short-out the other rectifiers in that group.

Shorted rectifiers deliver AC to the filter capacitors. This is not a

serious problem for non-polarized capacitors. However, with polarized

electrolytic capacitors, even a small episode of reverse-current can

damage the capacitor--or even cause it to explode. Thus, one

defective 10¢ diode can trigger the destruction of many dollars

worth of good parts. It is better to cull-out bad parts prior to

construction.

Silicon-rectifiers: Each diode should be tested individually where

possible. Increasing reverse voltage is applied to the DUT until a

leakage-current of approximately 2uA is detected. [high-current

diodes can withstand more reverse current] At this point it is

important to observe the current meter. If the leakage-current

randomly fluctuates without adjusting the voltage, the diode has a

manufacturing defect and it should be discarded. Since it is

difficult to mark each diode, I usually sort diodes into labeled

drawers according to PIV. Individual diodes which test greater than

about 1.3kV should be viewed with suspicion because this usually

indicates a doping problem. A forward voltage-drop test at the rated

current can be used to discover whether such a diode has a problem.

At 1A, the forward voltage drop in a silicon PN rectifier junction

should be less than 0.9V.

Transistors are now made with voltage capabilities that are similar

to silicon-rectifiers. Some transistors are rated at 1500V. Testing

these devices is similar to testing silicon-rectifiers--except that a

resistor of roughly 100 Ohm should be connected from the base to the

emitter, or from the gate to the source.

Air-variable capacitors: Identifying too-closely spaced points that

need realignment is easy with a voltage breakdown-tester.

Gridded power tubes need a good vacuum in order to function properly.

A vacuum test is made with no filament voltage applied. HV is applied

between the anode and a grid. A healthy 3 - 500Z will typically

exhibit less than 10uA of current-leakage at double the rated

anode-voltage.

The BVT can also be used to check the alignment of the filament in a

3-500Z. When its filament is cold, a healthy 3-500Z can withstand 7 -

8 kV between its grid and filament. If the filament is not concentric

with the grid, the breakdown voltage will be lower. This problem is

usually brought about by intermittent VHF parasitic oscillations--a

condition that generates a large pulse of cathode and grid currents.

The principle is simple: a flow of electrons is always accompanied by

a magnetic force. The larger the current, the stronger the force.

During an intermittent VHF parasitic oscillation, the magnetic force

is sometimes strong enough to bow the hot, tungsten filament wire

helices toward the grid. If the [cold] filament to grid

withstanding voltage of a 3 - 500Z is less than 6kV, a grid to

filament short may occur when the tube is hot.

Testing for parasitic damage in 8874s, 8877s, 3CX800A7s and other

oxide-cathode type tubes:

Such tubes have the following things in common: indirectly heated

strontium-oxide/barium-oxide cathode, high gain, ultra high frequency

capability, and gold-plated grid. The oxide-coating is an efficient

electron-emitter. The gold plating helps to reduce primary

electron-emission from the grid. This improves performance. There is

a tradeoff. If the gold evaporates [sputters], the loose gold

particles can cause serious problems.

In a vacuum, gold does not begin to evaporate unless it is heated to

more than 1000ºC [1832ºF]. Heating the entire mass

of the grid to >1000ºC requires more energy than is

available. However, if there were a way to heat the gold plating,

without heating the entire grid, gold evaporation would be possible.

VHF/UHF energy has a substantial "leg up" when it comes to heating

metal plating. VHF/UHF current travels exclusively on the surface.

During an intermittent VHF parasitic-oscillation, the VHF

grid-current can become so large that the surface of the gold plating

briefly becomes hot enough to evaporate gold. The resulting gold

vapour cloud can then move about freely inside the envelope. As the

gold cools, it solidifies into tiny balls. In a low power microscope,

they look like dew drops of water on the petal of a flower. Some of

the evaporated gold lands on the emissive coating. Gold poisons the

cathode's electron-emitting ability--causing a reduction in

anode-current and power output. [A copy of a letter from Eimac

describing this phenomenon is available on request to this

author.] Evaporated gold can also land on the inside of the

ceramic anode-insulator. This can cause arcs between the anode and

the adjacent (grounded) grid-ring. An arc is most likely during the

crest in the anode-voltage swing when the tube is not conducting--as

the HF tank-circuit/flywheel swings to its positive voltage peak. At

this instant, the peak anode-voltage is normally about double the

positive supply voltage. If the insulating ability of the ceramic has

been compromised by the presence of gold, trouble is probable. When

the anode arcs to the grounded grid, the HV-positive circuit is

virtually grounded. Thus, the HV-negative circuit tries to rise above

ground to the voltage in the HV filter capacitors. This typically

causes damage to components in the HV negative circuit. A common

problem is an arc between the cathode and the heater or an arc

between the cathode and the grid. Test for compromised voltage

withstanding ability between the heater and the cathode--and a burned

out heater.

The Loose Gold Test (W6IHA): There is a simple test that can

confirm the existence of loose gold particles without sawing open the

suspect amplifier-tube. The only piece of equipment needed is a BVT.

The principle behind the test: Like charges repel and unlike charges

attract.

Procedure: Remove the amplifier-tube from the amplifier. The positive

and negative DC-voltages that are applied between the anode and the

grid should be two to three times the operational anode-voltage.

Loose gold particles can be moved around by changing the polarity of

the anode-voltage. If the anode is positive, the gold particles are

attracted toward the anode-insulator. This causes the indicated

leakage current to increase. If the anode is made negative, the gold

particles are repelled and the leakage current will decrease. If the

leakage current is equal with either polarity, the presence of gas is

indicated.

Another method of confirming the presence of loose gold particles is:

apply positive anode-voltage and record the leakage current. Shut

down the BVT and, with the tube vertical and the anode-cooler up,

repeatedly bang the anode-cooler, both vertically and horizontally

with a approximately 2oz. soft face hammer. This will cause some of

the loose gold particles to fall to the bottom where they will be

less attracted by the positive voltage at the anode. Keep the tube

vertical. Re-apply positive anode-voltage. If the leakage current

decreases, you have loose gold and you are making progress. If the

leakage current does not decrease, either you need to bang harder or

no more improvement is possible. This procedure has been used by some

amplifier owners to get more operating hours out of gold sputtered

tubes. Banging also causes the gold to fall off the cathode coating.

This increases electron-emission. However, if the tube is turned

upside down, the loose gold becomes redistributed and the banging

process must be repeated to move the errant gold to a safer

place.

CIRCUIT ALTERATIONS:

Although T2 in the diagram has one side of the secondary grounded

internally, some transformers have no secondary terminal grounded.

This is a small advantage since it allows the BVT outputs to float if

needed.

There are many things that can be altered to accommodate available

parts--or to change the voltage capability of the tester. Ohm's Law

is the most important guide.

The wattage of the current-limiting lamp should be approximately

twice the wattage or VA rating of the HV transformer.

It is important to note that resistors have a dissipation-rating and

a voltage-rating. The voltage-rating always takes precedent over the

sometimes-phony dissipation-rating. For example: A 5.1M Ohm, 2W,

±5% resistor has a dissipation-rating that could lead a designer

to assume that the resistor could safely dissipate 2W. Using Ohm's

Law, E = [PR] 0.5 = [2W x 5.1M]

0.5 = 3193V at 2W. However, there's a catch. The resistor

is limited to 500V maximum by the technical specifications. This

means that the "2W" max. resistor is really {P = E2 / R, =

500v x 500v / 5.1M Ohm =} a 0.049W max. resistor! It pays to read the

specifications. High voltage resistors have a long, spiral,

resistive, deposited film that is designed to handle voltage.

- R8: The actual value of R8 is not critical. If you can not locate a

single resistor for R8, there is a commonly available spiral-film

resistor, that is marketed by ECG-Phillips, which has the right

properties. These resistors have a tolerance of ±2% and a

dissipation rating of 2W. They can be series wired on a perfboard to

build a satisfactory R8. One can be used for R9--whose function is to

help limit reverse. current through the DUT.

- C1 AND C2: It might seem necessary to use capacitors with a Working

Voltage [WV] rating that is equal or greater than the actual

V that will be encountered. However, voltage testing components is an

intermittent application that produces virtually zero ripple-current.

WV is a continuous duty rating--usually at an elevated temperature

and for a substantial amount of ripple current.

For BVT intermittent service at normal room temperatures, a WV-rated

capacitor can usually be used at 1.5 times its rating with no

difficulty. Sprague Vitamin-Q capacitors are very conservatively

rated. They can usually be used at double their WV rating in BVT

service.

If you are going to use tubular glass-case capacitors with metal

screw end-connections, it is important to put a stop-nut between the

capacitor and the mounting hole. The stop-nut prevents the screw

[which is soft-soldered to the end-cap] from being pulled out

of the capacitor when the outside fastening nut is tightened. Four

nuts are required to properly mount each capacitor. It is not

appropriate to mount this type of capacitor by only one end.

Metal-cased capacitors should be mounted without metal clamps on an

insulated surface. Use silicone rubber adhesive for mounting.

OPERATING NOTES:

Reasonable care should be used with a BVT. Although the

steady-current capability of this BVT is quite limited--even without

R8--a substantial [as in rudely awakening] current pulse can

be delivered by a charged capacitor.

When testing with voltages above about 8kV, it is possible to have a

false current indication caused by corona from sharp points. To check

for this problem, disconnect one end of the DUT, increase the voltage

and observe the current reading on M2. . . Rich, AG6K

(805)-386-3734.